Micro LED display

Micro LED technology has surpassed the limitations of OLED, with higher brightness and saturation. In addition, OLED materials are organic light-emitting diodes, which naturally cannot be compared with organic light-emitting diodes such as Micro LED in the service life. Micro LED is more competitive in the application fields requiring the use of time, such as car head-up display and large screen projection. Vacuum plasma in oxygen and nitrogen and add less vacuum plasma in oxygen and nitrogen and add a small amount of carbon tetrachloride, under the condition of discharge, can quickly etch off epoxy resin. 3. Will vacuum plasma completely destroy epoxy resin? Because of the gap between the Mini LED and the surface of the Mini LED, the epoxy resin has a poor thickness, so the vacuum plasma will preferentially etch the epoxy resin on the surface of the Mini LED chip.

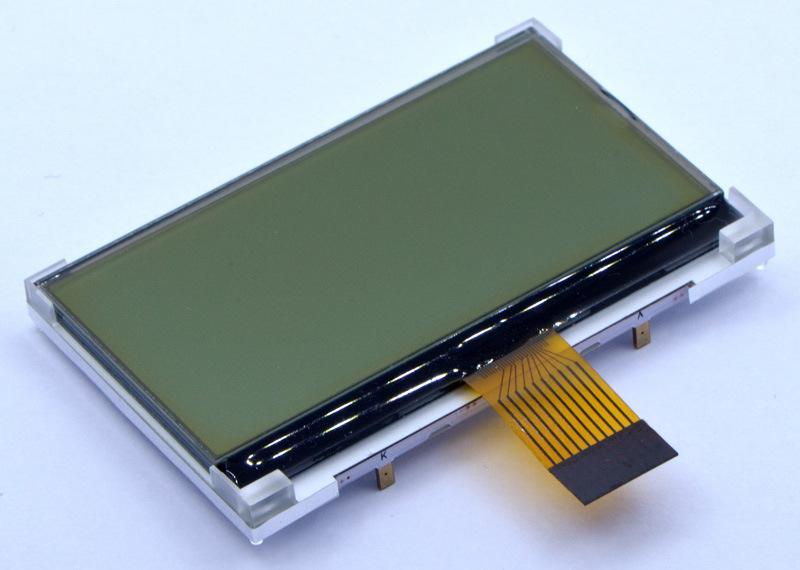

Box/yellow light CELL

In the whole process of LCD/TFT and other display modules, plasma equipment is used for surface activation and modification many times in the process of box forming/yellow light CELL, which greatly improves the stability of the process.

ITO pretreatment before coating

Plasma cleaning machine treatment can improve the surface topography of ITO better, and it can be seen that the oxygen holes on the surface of ITO increase significantly, and a layer of negatively charged oxygen is enriched on the surface to form an interface dipole layer, which increases the surface work function of ITO and greatly enhances the hole injection ability of ITO. In addition, after the treatment of plasma cleaning machine, the surface roughness of ITO is reduced, the interface between ITO film and NPB can be reduced, the hole injection becomes easier, and the electron injected by the cathode is better combined to generate excitons, and the device prepared by the anode after plasma treatment has high brightness and good quality.

ACF-FPC cable bonding

After the gold finger is cut by the Laser of the flexible plate, black carbide will appear on the edge, micro-short circuit will be generated in the high pressure test, and detachment phenomenon will occur at high temperature, which seriously affects the reliability and stability of the product and greatly reduces the quality of the product. Using OKSUN low-temperature plasma technology can completely remove black carbides and other pollutants on the molding edge, form a large number of active groups on the surface, serious pressing reliability, eliminate short circuit phenomenon.

COG display chip binding

In the COG process of installing bare chip IC on the glass substrate (LCD), when the chip is bonded and hardened at high temperature, the substrate coating composition on the surface of the bonding filler is analyzed. There are also cases where Ag slurry and other connectors overflow and contaminate the bonding filler. If these contaminants can be removed by plasma cleaning prior to the hot pressing binding process, the quality of the hot pressing binding can be greatly improved. Furthermore, as the wettability of substrate and bare chip IC surfaces is improved, the bonding and densivity of LCD-COG module can also be improved, and the problem of line corrosion can be reduced.

- 在線咨詢

- 微信咨詢

微信掃碼咨詢

- Tel

- Phone0755-81452366

- Tel13510501616

- Top